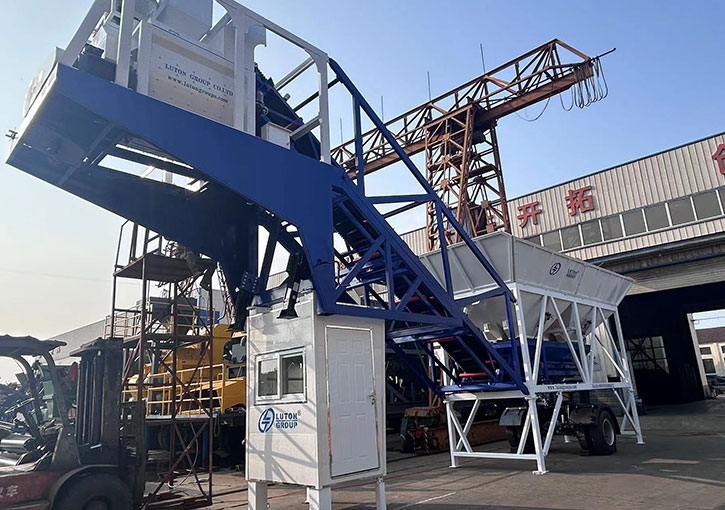

Mobile Concrete Plant On Luton Group

One mobile concrete batching plant – multiple applications fulfilled. Get maximum investment return with Luton manufacturer. High mobility, High efficiency, High producitivity – but with Low operating costs.

From 25m³/h to 100m³/h capacity, find the ideal mobile concrete batching plant for quality concrete manufacturing.

QUALITY

WE PROVIDE THE BEST QUALITY MOBILE CONCRETE BATCH PLANT AND EXCELLENT SUPPORT SERVICE

Designed for versatility and ease of transport, our mobile concrete plant ensures a steady supply of high-quality concrete directly on your job site.

With a robust capacity ranging from 25 to 120 cubic meters per hour, it’s built to cater to projects of any scale.

Whether for infrastructure development, residential construction, or commercial projects, our plant delivers unmatched efficiency. Don’t let logistics limit your potential; take control of your concrete supply and maximize productivity.

Inquire now to learn more and take the first step towards streamlined operations. Contact us today for a quote and elevate your construction capabilities!

Investment

Cost-Benefit Analysis: Is a Mobile Concrete Plant Worth the Investment?

Investing in a mobile concrete plant can be a significant financial decision for any construction business. The primary benefit of a mobile concrete plant is its flexibility; it can be transported to various sites, reducing the need for long-distance haulage of concrete. This not only cuts transportation costs but also ensures the delivery of fresh concrete with optimal workability and setting time, enhancing the quality of construction projects.

Moreover, a mobile concrete plant offers tailored production, allowing for adjustments to the concrete mix as per the specific requirements of each job. This adaptability can lead to a more efficient use of materials and a reduction in waste, further contributing to cost savings.

However, the initial investment for a mobile concrete plant can be higher than that of a stationary plant. This cost is offset over time by the plant’s mobility, which leads to lower overall project costs and the ability to take on more projects due to the reduced lead times.

The return on investment (ROI) for a mobile concrete plant is also influenced by the frequency of its use. For companies with consistent, high-volume concrete needs across various sites, the investment is often quickly recuperated. In contrast, for businesses with sporadic use or those operating in a limited geographical area, the benefits may not justify the expense.

MODELS

Luton Mobile Concrete Plant For Sale

High mobility but with fewer installation costs, Luton mobile concrete batching plant optimizes the use of space, meeting the demands for frequent jobsite replacement.

Mobile Concrete Plant with Twin Shaft Concrete Mixer

YHZS35 Concrete Plant

Hot Selling Model

35m³/h

Capacity

JS750

Mixer Type

750L

Mixer Capacity

PLD1200

Matched Batcher

Large Stock

Ready for Shipment

YHZS50 Concrete Plant

Most Cost-effective

50m³/h

Capacity

JS1000

Mixer Type

1000L

Mixer Capacity

PLD1600

Matched Batcher

Large Stock

Ready for Shipment

YHZS60 Concrete Plant

Save 30% Overall Cost

50m³/h³

Capacity

JS1000

Mixer Type

1000L

Mixer Capacity

PLD1600

Matched Batcher

Large Stock

Ready for Shipment

YHZS75 Concrete Plant

Exported to 25 countries

75m³/h

Capacity

JS1500

Mixer Type

1500L

Mixer Capacity

PLD2400

Matched Batcher

Large Stock

Ready for Shipment

Mobile Concrete Plant with Drum Concrete Mixer

Drum Mixer Mobile Concrete Plant

Hot Selling Model

35m³/h

Capacity

JS750

Mixer Type

750L

Mixer Capacity

PLD1200

Matched Batcher

Large Stock

Ready for Shipment

Mobile Drum Mixer Concrete Plant

Most Cost-effective

50m³/h

Capacity

JS1000

Mixer Type

1000L

Mixer Capacity

PLD1600

Matched Batcher

Large Stock

Ready for Shipment

ONGOING RURAL OR URBAN CONSTRUCTION PROJECTS?

WE HAVE THE SOLUTION

Our Mobile Concrete Plant excels in urban construction, infrastructure projects, and remote locations, offering fresh, tailor-made concrete with flexibility and reduced transportation costs. Transform your site’s efficiency now!

Reach out to us to find your best mobile concrete batching mixing plant to boost work efficiency.

Talk to Our Expert

Send Email to:info@lutongroups.com

AUTOMATION

Mobile Concrete Plant Automation: Pros and Cons

The automation of mobile concrete plants brings numerous advantages, including increased production efficiency, consistency in concrete quality, and reduced labor costs. Automated systems ensure precise ingredient dosing, optimal mixing, and consistent product output, which are critical for meeting stringent construction standards. They also facilitate real-time monitoring and adjustments, minimizing human error and material waste.

However, the cons of automation include the significant upfront investment in technology and training. The complexity of automated systems can lead to a steeper learning curve for operators and may require additional support and maintenance. In remote areas, technical issues can cause delays if specialized technicians are not readily available.

Furthermore, over-reliance on automation may reduce the workforce’s skill level, as manual operations dwindle. This shift can impact employment and the development of hands-on expertise within the industry.

Price

What Is Mobile Concrete Plant Price?

The price of a mobile concrete plant can vary widely based on several factors, including its capacity, features, automation level, brand, and the specific needs of the end-user. Mobile concrete batching plant prices can range from around $10,000 for a basic, small-capacity model to upwards of $20,000 for a large, fully automated and high-capacity plant.

Entry-level mobile concrete plants with limited automation and a production capacity of around 20-30 cubic meters per hour might fall into the lower end of this price range. Mid-range models, offering better automation, higher production rates (around 50-100 cubic meters per hour), and additional features such as integrated cement silos and advanced mixing technologies, can cost between $10,000 and $30,000.

High-end models that offer capacities exceeding 100 cubic meters per hour, complete with cutting-edge technology, robust build quality, and extensive support services, command the highest prices.

COMPARISON

Mobile vs. Fixed Concrete Plants: A Detailed Comparison

Mobile and fixed concrete plants serve the same fundamental purpose—producing concrete—but they differ significantly in operation, flexibility, and cost implications.

Mobile concrete plants are designed for ease of transport and rapid setup, making them ideal for projects that require frequent relocation, such as road construction or repair. They offer high flexibility and can be brought directly to job sites, regardless of their remoteness, thus reducing transportation time for concrete and ensuring its freshness upon delivery. The compact design of mobile plants also means they occupy less space, which is a significant advantage on constrained sites.

In contrast, fixed concrete plants are stationary facilities set up for long-term projects. They are suitable for large-scale operations that demand high volumes of concrete, such as commercial construction and large infrastructure projects. Fixed plants often have higher capacities and can produce larger quantities of concrete more efficiently. They also tend to have a more extensive setup with dedicated space for raw materials and longer-term infrastructure.

However, the initial investment for a fixed plant is considerably higher compared to a mobile plant. Fixed plants also incur higher operational costs due to the permanent nature of the setup. Moreover, they lack the flexibility to move, which can lead to higher costs and logistical challenges if the project site is far from the plant.

ADVANTAGES

FOR BUILDING CONSTRUCTION

Our mobile concrete plant offers superior efficiency, automated processes, energy savings, exceptional quality, and unparalleled customer service.

Rapid Deployment Capability: Mobile concrete plants can be transported and set up quickly, allowing for on-site production in a matter of hours.

Self-contained Units: Equipped with onboard water and power systems, these plants operate independently, reducing reliance on local utilities.

Modular Design: Their modular construction allows for easy expansion or modification to meet the changing demands of different projects.

Integrated Control System: Advanced control systems offer precision mixing and real-time data monitoring, optimizing the concrete quality and consistency.

Environmentally Friendly: Some models feature dust collection and recycling systems, minimizing waste and environmental impact at construction sites.

SPECIFICATION

technical specification

Mobile Concrete Plant

| Type | YHZS25 | YHZS35/40 | YHZS50/60 | YHZS75/90 | ||

| Theoretical production capacity(m3/h) | 25 | 35 | 50 | 75 | ||

| Concrete mixer | Type | JS500 | JS750 | JS1000 | JS1500 | |

| Discharging capacity(L) | 500 | 750 | 1000 | 1500 | ||

| Aggregate size(Pebble/Macadam)(mm) | 80/60 | 80/60 | 80/60 | 80/60 | ||

| Matched Aggregate Batcher | PLD800 | PLD1200 | PLD1600 | PL2400 | ||

| Weighing Accuracy | Aggregate (KG) | 1500Kg ±2% | 2000Kg ±2% | 3000Kg ±2% | 3000Kg ±2% | |

| Cement(KG) | 300Kg ±1% | 450Kg ±1% | 900Kg ±1% | 1500Kg ±1% | ||

| Fly ash(KG) | Optional | |||||

| Water (KG) | 200Kg ±1% | 300Kg ±1% | 600Kg ±1% | 900Kg ±1% | ||

| Additive(KG) | 20Kg ±1% | 30Kg ±1% | 30Kg ±1% | 50Kg ±1% | ||

PROJECTS

Our Products On Worksite

INTEGRATION

Integrating a Mobile Concrete Plant into an Existing Fleet

Integrating a mobile concrete plant into an existing fleet requires strategic planning to ensure seamless operations and maximize the benefits of increased flexibility and responsiveness. The integration process begins with assessing the current fleet’s capabilities and identifying the gaps that a mobile plant will fill, such as the need for on-site mixing at remote locations or the ability to quickly respond to project changes.

Once the need is established, the next step is selecting a mobile concrete plant that complements the existing fleet in terms of production capacity, automation level, and compatibility with current mixing trucks and equipment. It’s crucial to consider the logistical aspects, including transportation, setup, and breakdown procedures of the mobile plant, to ensure that it aligns with the fleet’s operational flow.

Training is another critical component. Operators and support staff must be proficient in managing the new equipment. This involves understanding the intricacies of its automation systems, maintenance requirements, and safety protocols.

Coordination with existing project management and scheduling systems is also essential to optimize the use of the mobile plant alongside other assets. This may involve software integration or updates to ensure real-time tracking and efficient dispatching.

Finally, the integration should be evaluated for its financial impact, considering both the short-term costs and the long-term gains in productivity and market reach. By carefully managing these elements, the addition of a mobile concrete plant can significantly enhance the versatility and competitiveness of a concrete fleet.

LUTON

WE ARE THE BEST IN CONSTRUCTION

Founded in 1999, LUTON GROUP CO., LTD, as a joint stock company, has more than 20 years of exporting experience in manufacturing concrete plants, asphalt plants, self-loading mixers, crushers, dry mortar plants and various types of construction machinery.

100+

100+ Countries Exported

30,000+

30,000+ Mixers Sold

20+

20+ years of experience

100%

100% quality guaranteed

TESTIMONIAL

Happy Customers

The mobile concrete plant’s swift setup and dismantling times have greatly enhanced our ability to respond to changing project needs.

Danilo Hamoy

Purchase Manager

Impressed by the plant’s automation, which has streamlined our operations, leading to a noticeable uptick in productivity and cost savings.

Kemadjou Nana Elisée

Project manager

Your mobile plant’s robust performance in various weather conditions has ensured our projects remain on schedule, regardless of the climate.

Jaime Yovany Rodriguez

Project manager

CASES

Latest Global Cases

September 06, 2023

35 Free Foundation Concrete Plant in Sri Lanka

September 06, 2023

YHZS35 Concrete Plant Arrived Indonesia

January 18, 2023

90 Dry Mix Mortar Plant Working in Indonesia

November 28, 2023

Belt Conveyor Concrete Plant Arrived Sri Lanka

May 27, 2023

Working Site of Concrete Batching Plant in Uzbekistan

October 25, 2023

HZS50 Concrete Plant Transported to Malaysia

September 20, 2023

HZS50 Concrete Plant Used in Thailand

January 15, 2023

HZS90 Concrete Plant Working in Tanzania

March 09, 2023

YHZS35 Mobile Concrete Plant in Botswana

SHIPMENT

Our Shipment Process

Process

At every step of our shipment process, our dedicated team takes great care to ensure that your order is handled with the utmost professionalism and attention to detail. We understand the importance of your satisfaction, and we strive to exceed your expectations with every shipment.

Order

24 online for your order

Production

Pick from stock or produce

Package

Well packed and labeled

Shipment

7 days fast delivery

EQUIPMENT