Concrete Plant On Luton Group

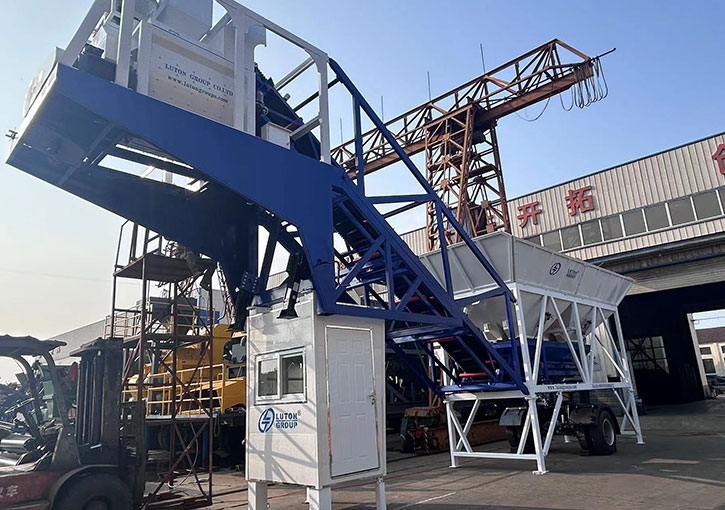

Exceeds all your expectations with Luton concrete batching plant – High quality materials, long component life, tailor-made service, high productivity, and beyond.

Get ideal construction equipment with either stationary or mobile concrete batching plant from Luton manufacturer. Our maximum 240m³/h plant capacity meets any of your construction applications. Start your economic choice with Luton now!

QUALITY

WE PROVIDE THE BEST QUALITY CONCRETE BATCH PLANT AND EXCELLENT SUPPORT SERVICE

Luton concrete batching plants are designed for ready-mix producers, contractors, precast manufacturers, and special applications. Furnished mainly with twin shaft mixers, also available with 0.5m³ and 1.5m³ planetary mixers.

The plants are available in various capacities ranging from 25m³ to 240m³ per hour of compacted concrete output and are designed for operations under extreme conditions with the highest performance. Special plant designs are available for dam construction and precast manufacturers. The design can adopt Ice dosing, Microsilica dosing, and some special additives very easily.

Ultimate modular design provides flexibility to adapt to site conditions and add on features as per project requirements. Specially cast wear-resistant parts keep maintenance time and cost at a very low level.

Investment

Why Invest In Luton Concrete Mixing Plant?

A concrete batching plant is among those acquisitions that will show to be a very good investment. It will certainly deliver actual worth in a short amount of time. Depending on your approaching building and construction project, it can show to be worth the investment from the day you obtain it and also establish it. Numerous businesses who buy concrete batching plants claim that they want they would certainly take the plunge faster as the advantages of such plants are wide-reaching.

Besides, with the higher demand for high-grade concrete, concrete plant prices will rise shortly, bringing tougher conditions for those who lack the budget.

That is why you should and must invest Luton concrete batching mixing plant, with high performance and delicate design, you will get a fast return on your investment within one year! Just call us to start your business now!

MODELS

Luton Concrete Batching Plant For Sale

Large capacity at a competitive price, 5 types of our concrete batching plant from Luton serve as a good solution for loads of concrete demands – accurate concrete output, and brilliant working performance.

Belt Conveyor Concrete Plant

HZS60 Concrete Plant

Best Seller

60m³/h

Capacity

JS1000

Mixer Type

300t/h

Belt Conveying

4.1m

Discharging Height

Large Stock

Ready for Shipment

HZS90 Concrete Plant

Hot Selling Model

90m³/h

Capacity

JS1500

Mixer Type

450t/h

Belt Conveying

4.1m

Discharging Height

Large Stock

Ready for Shipment

HZS120 Concrete Plant

Hot Selling Model

120m³/h

Capacity

MAO3000/2000

Mixer Type

550t/h

Belt Conveying

4.1m

Discharging Height

Large Stock

Ready for Shipment

HZS180 Concrete Plant

Highly Recommend

180m³/h

Capacity

MAO4500/3000

Mixer Type

650t/h

Belt Conveying

4.1m

Discharging Height

Large Stock

Ready for Shipment

HZS240 Concrete Plant

On Sale

240m³/h

Capacity

MAO6000/4000

Mixer Type

900t/h

Belt Conveying

4.1m

Discharging Height

Large Stock

Ready for Shipment

Skip Hopper Concrete Plant

HZS25 Concrete Plant

Hot Selling Model

25m³/h

Capacity

JS500

Mixer Type

500L

Mixer Capacity

PLD800

Matched Batcher

Large Stock

Ready for Shipment

HZS35 Concrete Plant

Exported to 20 Areas

35m³/h

Capacity

JS750

Mixer Type

750L

Mixer Capacity

PLD1200

Matched Batcher

Large Stock

Ready for Shipment

HZS50 Concrete Plant

Save 10% Overall Cost

50m³/h

Capacity

JS1000

Mixer Type

1000L

Mixer Capacity

PLD1600

Matched Batcher

Large Stock

Ready for Shipment

HZS75 Concrete Plant

For Multiple Use

75m³/h

capacity

JS1500

Mixer Type

1500L

Mixer Capacity

PLD2400

Matched Batcher

Large Stock

Ready for Shipment

Mobile Concrete Plant with Twin Shaft Concrete Mixer

YHZS35 Concrete Plant

Hot Selling Model

35m³/h

Capacity

JS750

Mixer Type

750L

Mixer Capacity

PLD1200

Matched Batcher

Large Stock

Ready for Shipment

YHZS50 Concrete Plant

Most Cost-effective

50m³/h

Capacity

JS1000

Mixer Type

1000L

Mixer Capacity

PLD1600

Matched Batcher

Large Stock

Ready for Shipment

YHZS60 Concrete Plant

Save 30% Overall Cost

50m³/h³

Capacity

JS1000

Mixer Type

1000L

Mixer Capacity

PLD1600

Matched Batcher

Large Stock

Ready for Shipment

YHZS75 Concrete Plant

Exported to 25 countries

75m³/h

Capacity

JS1500

Mixer Type

1500L

Mixer Capacity

PLD2400

Matched Batcher

Large Stock

Ready for Shipment

Mobile Concrete Plant with Drum Concrete Mixer

Drum Mixer Mobile Concrete Plant

Hot Selling Model

35m³/h

Capacity

JS750

Mixer Type

750L

Mixer Capacity

PLD1200

Matched Batcher

Large Stock

Ready for Shipment

Mobile Drum Mixer Concrete Plant

Most Cost-effective

50m³/h

Capacity

JS1000

Mixer Type

1000L

Mixer Capacity

PLD1600

Matched Batcher

Large Stock

Ready for Shipment

Dry Mix Concrete Plant

HZG90 Dry Mix Concrete Batching Plant

Designed For Multiple Use

90m³/h

Capacity

PLD2400

Matched Aggregate Batcher

1500Kg ±1%

Cement

600Kg±1%

Fly Ash

Large Stock

Ready for Shipment

HZG120 Dry Mix Concrete Batching Plant

Hot Selling Model

120m³

Capacity

PLD3200

Matched Aggregate Batcher

1500Kg ±1%

Cement

1500Kg±1%

Fly Ash

Large Stock

Ready for Shipment

Free Foundation Concrete Plant

FHZS35 Free Foundation Concrete Plant

Designed For Multiple Use

35m³/h

Capacity

750L

Mixer Discharging Volume

1200L

Mixer Feeding Volume

30kW

Mixer Motor Power

Large Stock

Ready for Shipment

FHZS50 Free Foundation Concrete Plant

Hot Selling Model

50m³/h

Capacity

1000L

Mixer Discharging Volume

1600L

Mixer Feeding Volume

18.5x2kW

Mixer Motor Power

Large Stock

Ready for Shipment

ONGOING RURAL OR URBAN CONSTRUCTION PROJECTS?

WE HAVE THE SOLUTION

Our concrete plant is used to produce large quantities of concrete efficiently. It’s crucial for construction projects such as building roads, bridges, dams, and other large-scale infrastructure, ensuring consistent quality and reducing labor costs.

Reach out to us to find your best concrete batching mixing plant to boost work efficiency.

Talk to Our Expert

Send Email to:info@lutongroups.com

FEATURES

Features of Concrete Mix Plant

There are several attributes that make an effective concrete batching plant. The main benefit needs to be precise weighing as well as reduced maintenance in addition to the smooth procedure.

The significant components of the concrete mixer available are the private weighing devices for aggregate, sand, concrete, water, ingredients, etc. material communication systems; blending system, material storage systems; control board, and various other optional components.

The main quality of this machine is to use concrete as a binding material to blend aggregates, sand, water some ingredients and also lastly produce concrete which can be immediately utilized as a material for building.

Considering the development of these precise devices, the building construction and also road building and construction jobs are on an increase. Obviously, the top-quality construction machines have played a crucial function below:

The devices are generally identified right into:

– Aggregate feeding

– Cement as well as fly ash feeding

– Water feeding

– Transfer zones

– Weighing zones for each and every item

– Mixing areas

– Storage chambers.

The body of the portable concrete batching plants by Atlas is taken of premium quality moderate steel. It is possible to take these tools to locations and additionally hassle-free to install as well as start the manufacturing. Such devices will have exceptional blending performance. The mixers are very established with high resistant plates which can endure torment. Twin shaft mixers are geared up with planetary gearboxes which are durable as well as can take torque easily. The blending system which is the core of the equipment helps in consistently blending concrete basically time.

In addition to the premium quality mixer, the equipment is likewise equipped with various accessories like a screw conveyor for transfer of concrete/ fly ash to the weighing ranges, pneumatically-driven sensing units, lots cells for weighing, pneumatic cylinders, air compressor, and so on. The components picked are all sourced from top quality suppliers as well as assurance dependable procedure of the devices.

Accurate working of the tons cells makes certain that the mix recipe is based on the requirement. As liable and high-quality concrete plant makers, we understand the importance of this device and also, therefore, we have actually created this device to be upkeep free. Because the blending unit will certainly call for maintenance as well as cleansing to be done during routine periods, there suffices space to move the mixing device.

The very same is true for various other components. The control board is extremely easy to use with a touch screen display as well as any kind of operator with basic knowledge of concrete plants can operate the same similar to a touch screen cellphone.

Characteristic

Luton Stationary Concrete Plant Characteristic

Twin-shaft Mixer

A horizontal twin-shaft compulsory mixer has a strong mixing ability, it can mix the materials evenly and effectively. It can mix concrete with different slumps and raw materials ratios.

Its mixing blade and lining board are made of high chromium wear-resistant alloy.

External shaft end support and special shaft seal ensure the long service life of the mixer.

Aggregates Batcher

The quantity of aggregate Bins depends on the customer’s requirements, usually three or four bins. A wheel loader can be used to transfer the aggregates to the aggregate bins.

At the bottom of the aggregate bin, there are one fine aggregate and one coarse aggregate discharging gate.

Once receiving signals, the cylinder will open the discharging gate, and the aggregates are discharged into the weighing hopper respectively.

Weighing System & Aggregate Conveying System

It has the function of automatic difference compensation, aggregates, cement, water fly ash, and additive all has their own weighing system, and the results are accurate.

After weighing, the aggregate is sent to the concrete mixer by the lifting hopper or belt conveying system.

principle

Working Principle of Concrete Mixer Plant

In operation, the concrete batching plant has 4 essential components. These are the crushed rock feed; Powder feed part (cement, fly ash, bulking agents), water and feed additives, transmission, and also storage space. The fundamental operation treatment of the equipment can be specified as,

· System Activation; the mixing formula is input through the control board, this likewise consists of the concrete slump, grade, and also productivity. This is the calibration that will be used for the specific elements of the mix.

· The hoppers are evaluated as well as adjusted for precision before the procedure begins.

· The belt conveyor is started to transfer the aggregate to the weighing hopper.

· The control valve of the water sump and admixtures are opened to allow water and also admixtures to stream right into the weighing hopper.

· When all weights have satisfied the called-for volumes the doors of the weighing hoppers are opened immediately.

· The materials are launched into the mixer where mixing continues until the setting time is over. The loading doors are after that opened up and also the mix streams into a concrete mixer truck.

· This procedure is done very meticulously to guarantee the concrete does not set apart, and it has to be utilized before the preliminary setup time of 30– 45 minutes is reached.

DETAILS

WE MAKE IT BEST IN EACH PART

From the meticulous selection of raw materials to the precision in batching, mixing, and delivering the concrete, we ensure excellence at each stage.

This unwavering dedication results in superior-quality concrete that stands the test of time, reinforcing our reputation as a trusted industry leader.

240m³/h

240m³/h Large Capacity

40%

40% Less Laboring Costs

100%

100% Automatic Process

20%

20% Electricity Saved

Components

Components of Concrete batching Plant

A concrete batching plant is a complex system that involves several components to ensure the efficient production of concrete. Here are the key components:

Aggregate Batcher/Bin

This is where different types of aggregates are stored. The aggregates are then weighed and batched as per the mix design before being sent to the mixing unit.

Cement Silos

These are large storage containers used to store bulk amounts of cement. The cement is then dispensed into the mixer in the correct proportions.

Concrete Mixer

This is the component where the cement, aggregates, and water are mixed together to form concrete. The mixer ensures that the concrete is uniform and consistent.

Weighing System

This system measures the exact quantities of each ingredient to ensure the correct mix ratio. It usually includes separate scales for water, cement, and aggregates.

Control System

This is the brain of the plant. It controls the operations of the batching plant, including the mixing time and the quantities of each ingredient to be mixed.

Conveyor Belts

These are used to transport the ingredients from the storage bins to the mixer.

Each of these components plays a critical role in ensuring that high-quality concrete is produced efficiently and consistently.

Reach Out to Us For More Gallery And Information!

Price

What Is Concrete Batching Plant Price?

The prices of concrete batching plants vary between $21,000 and $280,000, depending on the production capacity and also the specification of the plant you wish to acquire. Besides equipment procurement price, some other outlay, such as setup cost, material acquisition cost, upkeep price, workers’ earnings, and insurance policy expenses, issue a lot that to some extent they choose the revenue margin. Nevertheless, simply a concrete plant itself cannot bring an advantage to you.

Currently, there are lots of types of concrete mixing plants in the marketplace. Different devices have various craftsmanship and efficiencies, and their prices are likewise different. To acquire or purchase a concrete mixing plant, it needs to first determine the anticipated production range of the project, determine the capacity, model, and setup of the concrete mixing plant, and finally, choose the equipment based upon this information.

| Models | Approximately Price |

| Belt Conveyor Concrete Plant | $14,000 – $70,000 |

| Skip Hopper Concrete Plant | $14,000 – $70,000 |

| Mobile Concrete Plant | $14,000 – $70,000 |

| Dry Mix Concrete Plant | $14,000 – $70,000 |

| Containerized Concrete Plant | $14,000 – $70,000 |

| Free Foundation Concrete Plant | $14,000 – $70,000 |

COST

Cost of Running Concrete Plants Project

The overall price for a concrete plant depends upon its type (ready mix, central mix, mobile/stationary, production capacity, the existing cost of raw materials as well as various other costs like labor as well as estimated hrs in operation. The area often imposes influences on it also. Some critical aspects you’ll need to account for are detailed as follows.

Production Capacity

The production capacity of a concrete mixing plant is different, and the price that is required to be invested varies.

One is the gadget itself. The better the production capacity of the equipment, the higher the purchase cost;

Secondly, the various production capacity suggests that the demand for raw materials such as cement, crushed rock, sand, and also fly ash is various, which will cause an increase in the capital investment of the whole project.

The production capacity of concrete mixing plants for tiny and also medium-sized projects is below 90m³/h, as well as the production capacity of concrete mixing plants needed for massive production, is typically 120m³/h-270m³/h.

Type and Model

To purchase a concrete mixing plant, you need to first identify what type and model of devices you need. The prices of different concrete mixing plants are different, and also the gap is not tiny. Consumers can pick the equipment model according to their actual scenario, select the model, and select the economical devices.

Site Construction Expense

In addition to the concrete manufacturing equipment, the initial financial investment required to set up a concrete plant likewise consists of the cost of the site, the construction of the office complex and dormitories, and also the cost of constructing a shut-material yard to meet environmental management criteria.

Various Operation Costs

The later operation of the concrete mixing plant includes water as well as electrical power costs, workers’ wages, raw material purchase prices, loaders, as well as concrete transport lorries, which should be considered before investing.

Various Handling Fees

Investing in a concrete batch plant requires going through different treatments, and these treatments are likewise expensive. These additionally require to be allocated as the investment cost of constructing the mixing plant. There is one more point that requires to be focused on.

The financial investment cost of a commercial concrete batching plant is higher than a general design concrete mixing plant. The design of concrete mixing station shall fulfill the demands of the project, as well as unnecessary features, can be disposed of, as long as the top quality of the concrete fulfills the requirements of the project. The industrial concrete batching plant should have the ability to generate concrete with a range of typical tags, as well as sometimes required to meet the unique requirements of customers. The control system needs to be completely automatic, and it additionally needs to have a storage space feature to boost work performance.

ADVANTAGES

FOR BUILDING CONSTRUCTION

Our concrete plant offers superior efficiency, automated processes, energy savings, exceptional quality, and unparalleled customer service.

A centralized concrete batching plant can serve a large room.

The plants are located in areas for industrial usage and also supply vehicles that can serve residential districts or inside cities.

Much better quality concrete is created.

Elimination of storage space for basic materials on site.

Elimination of hiring of plant and also equipment.

The wastefulness of raw materials is prevented.

Workers related to the production of concrete are removed.

The moment called for is considerably minimized.

Noise and dust contamination on the site are minimized.

SPECIFICATION

technical specification

Belt Conveyor Concrete Plant

| Type | HZS60 | HZS90 | HZS120 | HZS180 | HZS240 | ||

| Theoretical production(m³/h) | 60 | 90 | 120 | 180 | 240 | ||

| Concrete mixer | Type | JS1000 | JS1500 | MAO3000/2000 | MAO4500/3000 | MAO6000/4000 | |

| Power(KW) | 18.5×2 | 22×2 | 37×2 | 55×2 | 75×2 | ||

| Discharging capacity(L) | 1000 | 1500 | 2000 | 3000 | 4000 | ||

| Aggregate size(Pebble/Macadam)(mm) | 80/60 | 80/60 | 80 | 80 | 80 | ||

| Belt conveying Capacity(t/h) | 300 | 450 | 550 | 650 | 900 | ||

| Weighing Accuracy | Aggregate (KG) | 3000Kg ±2% | 3000Kg ±2% | 3000Kg ±2% | 3000Kg ±2% | 3000Kg ±2% | |

| Cement(KG) | 1500Kg ±1% | 1500Kg ±1% | 1500Kg ±1% | 1800Kg ±1% | 2200Kg ±1% | ||

| Fly ash(KG) | 600Kg ±1% | 900Kg ±1% | 400Kg ±1% | 500Kg ±1% | 800Kg ±1% | ||

| Water (KG) | 600Kg ±1% | 900Kg ±1% | 500Kg ±1% | 800Kg ±1% | 1000Kg ±1% | ||

| Additive(KG) | 50Kg ±1% | 100Kg ±1% | 100Kg ±1% | 100Kg ±1% | 100Kg ±1% | ||

| Discharging height(M) | 4.1 m | 4.1m | 4.1m | 4.1m | 4.1m | ||

Skip Hopper Concrete Plant

| Type | HZS25 | HZS35 | HZS50 | HZS75 | HZS100 | HZS150 | HZS200 | |

| Theoretical Production Capacity(M3/H) | 25 | 35 | 50 | 75 | 100 | 150 | 200 | |

| Concrete Mixer | Type | JS500 | JS750 | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 |

| Discharging Capacity(L) | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | |

| Aggregate Size(Pebble/Macadam)(Mm) | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Matched Aggregate Batcher | PLD800 | PLD1200 | PLD1600 | PL2400 | PLD3200 | PLD4800 | PLD6400 | |

| Weighing Accuracy | Aggregate (KG) | 1500Kg ±2% | 2000Kg ±2% | 3000Kg ±2% | 3000Kg ±2% | 3000Kg ±2% | 3000Kg ±2% | 3000Kg ±2% |

| Cement(KG) | 300Kg ±1% | 450Kg ±1% | 900Kg ±1% | 1500Kg ±1% | 1500Kg ±1% | 1800Kg ±1% | 2200Kg ±1% | |

| Fly Ash(KG) | 600Kg ±1% | 900Kg ±1% | 400Kg ±1% | 500Kg ±1% | 800Kg ±1% | |||

| Water (KG) | 200Kg ±1% | 300Kg ±1% | 600Kg ±1% | 900Kg ±1% | 500Kg ±1% | 800Kg ±1% | 1000Kg ±1% | |

| Additive(KG) | 20Kg ±1% | 30Kg ±1% | 30Kg ±1% | 50Kg ±1% | 100Kg ±1% | 100Kg ±1% | 100Kg ±1% | |

Mobile Concrete Plant

| Type | YHZS25 | YHZS35/40 | YHZS50/60 | YHZS75/90 | ||

| Theoretical production capacity(m3/h) | 25 | 35 | 50 | 75 | ||

| Concrete mixer | Type | JS500 | JS750 | JS1000 | JS1500 | |

| Discharging capacity(L) | 500 | 750 | 1000 | 1500 | ||

| Aggregate size(Pebble/Macadam)(mm) | 80/60 | 80/60 | 80/60 | 80/60 | ||

| Matched Aggregate Batcher | PLD800 | PLD1200 | PLD1600 | PL2400 | ||

| Weighing Accuracy | Aggregate (KG) | 1500Kg ±2% | 2000Kg ±2% | 3000Kg ±2% | 3000Kg ±2% | |

| Cement(KG) | 300Kg ±1% | 450Kg ±1% | 900Kg ±1% | 1500Kg ±1% | ||

| Fly ash(KG) | Optional | |||||

| Water (KG) | 200Kg ±1% | 300Kg ±1% | 600Kg ±1% | 900Kg ±1% | ||

| Additive(KG) | 20Kg ±1% | 30Kg ±1% | 30Kg ±1% | 50Kg ±1% | ||

Dry Mix Concrete Plant

| Type | HZS25G | HZS35G | HZS50G | HZS60G | HZS75G | HZS90G | HZS100G | |

| Theoretical production capacity(m3/h) | 25 | 35 | 50 | 60 | 75 | 90 | 100 | |

| Matched Aggregate Batcher | PLD800 | PLD1200 | PLD1600 | PLD1600 | PL2400 | PLD2400 | PLD3200 | |

| Weighing Accuracy | Aggregate (KG) | 1500Kg ±2% | 2000Kg ±2% | 3000Kg ±2% | 3000Kg ±2% | 4500Kg ±2% | 4500Kg ±2% | 4500Kg ±2% |

| Cement(KG) | 300Kg ±1% | 450Kg ±1% | 900Kg ±1% | 900Kg ±1% | 1500Kg ±1% | 1500Kg ±1% | 1500Kg ±1% | |

| Fly ash(KG) | 500Kg ±1% | 600Kg ±1% | 600Kg ±1% | 600Kg ±1% | 600Kg ±1% | 600Kg ±1% | 1500Kg ±1% | |

| Water (KG) | 200Kg ±1% | 300Kg ±1% | 600Kg ±1% | 600Kg ±1% | 600Kg ±1% | 600Kg ±1% | 1000Kg ±1% | |

| Additive(KG) | 20Kg ±1% | 30Kg ±1% | 100Kg ±1% | 100Kg ±1% | 100Kg ±1% | 100Kg ±1% | 100Kg ±1% | |

Containerized Concrete Plant

| Specifications | HZS-60C | HZS-90C | HZS-120C | HZS-180C |

| Theoretical Productivity (m3/h) | 60 | 90 | 120 | 180 |

| Mixer Discharging Volume (L) | 1000 | 1500 | 2000 | 3000 |

| Mixer Feeding Volume (L) | 1600 | 2400 | 3200 | 4800 |

| Mixer Motor Power (kW) | 18.5×2 | 30×2 | 37×2 | 55×2 |

| Discharging Height (m) | 4.1 | 4.1 | 4.3 | 4.3 |

| Aggregate Material Quantity (m3) | 7×4 | 15×4 | 15×4 | 20×4 |

| Cycle Period (s) | 60 | 60 | 60 | 60 |

| Max. Aggregate Size (mm) | 80/100 | 80/100 | 80/100 | 80/100 |

| Cement Silo (t) (optional) | 2×100 | 3×100 | 4×100 | 4×100 |

| Aggregate Weighing System | ±2% | ±2% | ±2% | ±2% |

| Powder Material Weighing System | ±1% | ±1% | ±1% | ±1% |

| Water Weighing System | ±1% | ±1% | ±1% | ±1% |

| Additive Weighing System | ±1% | ±1% | ±1% | ±1% |

| Installation Power (kW) | = 110 | = 160 | ^220 | ◎290 |

| Feeding Mode | Skip Hopper and Belt Conveyor | |||

| Control Mode | Full Automate Computer PC Control | |||

Free Foundation Concrete Plant

| Specifications | FHZS-25 | FHZS-35 | FHZS-50 | FHZS-75 |

| Theoretical Productivity (m3/h) | 25 | 35 | 50 | 75 |

| Mixer Discharging Volume (L) | 500 | 750 | 1000 | 1500 |

| Mixer Feeding Volume (L) | 800 | 1200 | 1600 | 2400 |

| Mixer Motor Power (kW) | 18.5 | 30 | 18.5×2 | 30×2 |

| Aggregate Material Quantity (m3) | 3×3 | 5×3 | 8×3 | 12×3 |

| Cycle Period (s) | 60 | 60 | 60 | 60 |

| Max. Aggregate Size (mm) | 80/100 | 80/100 | 80/100 | 80/100 |

| Cement Silo (t) (optional) | 50×1 | 50×1 | 100×1 | 100×2 |

| Aggregate Weighing System | ±2% | ±2% | ±2% | ±2% |

| Powder Material Weighing System | ±1% | ±1% | ±1% | ±1% |

| Water Weighing System | ±1% | ±1% | ±1% | ±1% |

| Additive Weighing System | ±1% | ±1% | ±1% | ±1% |

PROJECTS

Our Products On Worksite

CHOOSE

How to Choose A Concrete Plant?

Buying a concrete plant needs a lot of pondering and believing very carefully about numerous facets, evaluating advantages and disadvantages, checking into the economic issues, and more. So, just how can you choose concerning acquiring a concrete plant? e have actually put together the top seven features to be thought about before purchasing a concrete mixing plant.

1. Building And Construction Atmosphere, Batching Plant Capacity & Other Related Variables

The construction environment is among the leading factors to be considered while purchasing a concrete plant. So ask on your own the following concerns:

– What is the dimension of the building and construction site?

– Accordingly, what should be the dimensions of the devices?

– Similarly, how much quantity of concrete would certainly be needed for the project?

– Just how active is the area near the building site in regards to traffic?

– What is the range between the building site and the conveying vehicle?

2. Integrity of the Equipment

The reliability of the devices and also the quality of the concrete created go hand in hand. Hence, it is necessary to make certain that the batch plant is reputable to get top-quality concrete for your building and construction job. Think about the adhering to elements:

– Inspect the various product attributes

– Examine the control system of the equipment

– Search for personalization choices

– Analyze the product parameters to ensure they meet your

– requirements and requirements

3. Conduct Batching Plant Cost Evaluation

Given that there are several concrete batching plant alternatives offered, it is suggested to establish your spending plan and make a cost analysis of the devices you need. It consists of:

– Transport costs

– Setup prices

– Site preparation expenses

– Electrical and also plumbing prices

4. Performance/Cost Ratio

When it refers to the financial aspects, you have to carry out a complete evaluation. It is not adequate to just check out the rate of the concrete plant. You need to also think about the performance-cost ratio. In other words, look for equipment that supplies much more advantages at much less expense. It will raise the performance-cost ratio.

5. Selection of Main Engine

The primary engine of a concrete batching plant has to be chosen after due care and also inspection. You have to seek the following qualities:

– Dependable concrete mixer

– Capability to produce good quality concrete

– Needs to have solid overload capacity

– Should have high production efficiency

– Must have the versatility to the mixing of different commodities

6. Watch out for Accumulation of Options

It is a very critical aspect to be considered while purchasing a concrete batching plant. So be familiar with the kind of cement readily available in your area. It will be the deciding element as the variety of bins for the plant is a concern.

7. Worth of the Producer’s Brand

It is essential to go with a producer that is well-known and dependable. You should request the following:

– The innovation utilized

– Quality of products used to put together the equipment

– After-sales services provided by the producer

– Whether the maker offers training on risk-free and also efficient use as well as routine upkeep as well as upkeep of the concrete plant.

The essential facet while choosing a concrete plant is to look for the most effective mix of high quality and rate, i.e., the equipment must be of exceptional top quality at an affordable cost.

types

Major Types of Concrete Plant

Mobile Concrete Batching Plant

Mobile plants consisting of portable shaft mixers are developed to be portable as well as thus are set up on towable framework with wheels for maximum mobility and also quick arrangement.

Mobile batching plants are excellent for temporary building and construction sites or construction projects where the devices would only be needed for specific as well as brief parts of the projects. Mobile concrete devices can be quickly mounted as well as taken down and because of this require really minimal preparation or established prior to usage.

Mobile concrete batching plants come pre-wired with optimum devices set up to guarantee rapid installment on site. Commonly a standard mobile plant can be set up in 1-2 days.

Stationary Concrete Batching Plant

In the stationary concrete batching plants, cement is mainly used as a binding material for mixing sand, water, and aggregates and also significant ingredients too to create concrete in a quick way for the civil building projects.

The celebration conveyor belt runs below the bins where weighing of aggregates happens and the aggregate are then discharged onto the charging conveyor. Pneumatically operated gateways are attended to discharge of the aggregate on to the celebration conveyor. The material is all weighed properly as well as transferred to the twin shaft mixer through a slinger conveyor.

These stationary concrete plant pneumatics used are of reputed make which guarantee long life and also superior efficiency for your machine. The Stationary Plants are offered in various capacities varying from 30 m3 to 240 m3 per hour of compacted concrete output.

In the current Stationary concrete plants, the aggregates are kept in horizontal bins. The event conveyor belt runs below the containers where the weighing of aggregates happens and the aggregates are then discharged onto the charging conveyor. Pneumatically operated entrances are attended to discharge of the aggregate onto the gathering conveyor.

The material is all weighed properly and moved to the twin shaft mixer via a slinger conveyor. The new batching plants likewise feature the Skip Hoist and also Belt setup choice for mixer loading. The information designs can adopt silica application and some special additives really easily.

Transit/ Dry Mix Concrete Batching Plant

Contemporary dry mix concrete plant consists of the cement silos, feeding system, control system, weighing system and mixing system. Cement silos are the container to maintain and also provide resources such as concrete, sand, and also fly ash according to the need of the manufacturing.

The feeding system is a bridge to connect the aggregates and the mixing system. The accuracy of the weighing system figures out the quantity of the mixed materials, so it has a great result on the quality of mixed concrete. Dry mix concrete batching plants just weigh all the materials based on concrete formula, and then discharge them right into concrete mixer trucks. The procedure of mixing all materials is carried out in a concrete mixer truck.

Throughout the procedure, a concrete mixer truck is accountable for both transportation as well as mixing. Dry mix concrete batching plant does not have the mixing system as the one “wet mix” concrete batching plant possesses.

Consequently, the dry mix concrete batching plant overcomes some inherent flaws of the “wet mix” concrete batching plant has, which is not just suitable for the working conditions of the wet mix concrete batching plant, however also for extreme conditions such as heat, high warmth, high elevation and long transportation range etc.

Wet Mix Concrete Batching Plant

Modern wet batching concrete plants integrate all the ingredients needed to make concrete prior to it’s relocated to the mixing trucks. Central-mix batching plants use plant-mounted mixers where you place all the concrete ingredients.

Latest-model adopts a twin shaft paddle mixer, which has a solid mixing high quality. This can guarantee there is no or much less residual in the twin shaft concrete mixer, save materials and save cost. With a Central Mix plant, all lots see the very same mixing activity as well as there is a first quality assurance factor when releasing from the main mixer.

Wet mix plants come in versatile as well as stationary designs. The most effective mechanical style infiltrated the item seeks for consistent mixing without detachment, right proportioning and mixing of aggregates and included substances. The wet mix plant communicates precisely mixed chilly mix, solution treated mixes etc.

Portable Concrete Batching Plant

Compact Concrete Batching Plants are made up of smaller sized systems of pre-designed or pre-wired production devices that are typically moved in batches to be lastly put together at the site they are to be used. This makes sure that transport is both faster as well as simpler.

This portable style ensures that the portable concrete plant integrates some of the flexibility benefits of the mobile batching plants and also the efficiency prowess of the stationary concrete batching plant.

Portable concrete plant is developed to reduce deal with site throughout installment and also is plumbed as well as examined at the production facilities. This type of plant mostly carry the ingredients smartly as well as additionally lower the air pollution aspects emission.

Horizontal Concrete Batching Plant

Horizontal concrete batching plant collection has a straightforward but robust layout. The settings up are optimized for affordable transportation and quick setting up. A modern-day and easy-to-operate control system finish off the appealing total package.

A wide variety of concrete dishes are generated reliably and also in excellent quality. The plant is furnished with a powerful ring-pan mixer and also generates approximately 69m³ of fresh concrete per hr. Relying on the demands, the more recent design collection is equipped with a frying pan mixer or a twin-shaft mixer.

While designing the plant, high relevance was connected to the gain access to consequently helping with maintenance. Additionally, the generously dimensioned room enables this plant to be used in a wide variety which can be drawn from a modular system. These high capacity, sturdy plants are the first choice anywhere huge quantities of concrete are needed.

Inline Concrete Batching Plant

New generation inline concrete batching plant incorporated with advanced PLC innovation automation that permits to perform performances like broadband weighing, automated range tolerance checking, inventory monitoring, reports generation consisting of batch smart, tons smart, data wise, dish wise and manufacturing sensible reports for a much better and also cost effective concrete production process.

The recently designed Twin shaft mixer as well as Planetary Mixer enables efficient mixing of concrete with less wastefulness as well as boosted quality specifications with concrete mixing plant. This is a competent concrete production unit which is developed to offer optimal mixing performance while reducing the operation as well as production expenses with minimal upkeep required.

Containerized Concrete Batching Plant

The containerized concrete batch plant contains mixing system, control system, material storage space system, weighing system, conveying system as well as others. On top of that, the container mixing plant has the attributes such as little footprint, quick setup, convenient transport and more. Compared with the traditional concrete plant, the container mixing plant does not need to establish the legs and also placing brackets, removing basic design as well as construction.

The container concrete batching plant has outstanding ecological performance, practical transport as well as basic setup. It is suitable for supplying concrete manufacturing of numerous kinds such as hydropower, highways, ports, flight terminals, bridges and various other building projects, as well as the building of business concrete batching plants.

SOLUTION

MIXED MACHINE FOR HIGH EFFICIENCY – Concrete Batching Plant with Mixer Truck and Wheel Loader

The integration of a concrete batching plant, mixer truck, and wheel loader can greatly enhance operational efficiency and decrease overall costs in the construction process.

The batching plant, being the heart of the concrete production process, can be optimized for a streamlined workflow, reducing the time taken to load, mix, and unload concrete. The wheel loader plays a crucial role in swiftly loading aggregates into the batching plant, further speeding up the process. The mixer truck, on the other hand, ensures the concrete is mixed to the right consistency and delivered on time.

LUTON

WE ARE THE BEST IN CONSTRUCTION

Founded in 1999, LUTON GROUP CO., LTD, as a joint stock company, has more than 20 years of exporting experience in manufacturing concrete plants, asphalt plants, self-loading mixers, crushers, dry mortar plants and various types of construction machinery.

100+

100+ Countries Exported

30,000+

30,000+ Mixers Sold

20+

20+ years of experience

100%

100% quality guaranteed

TESTIMONIAL

Happy Customers

Our purchase of your concrete batching plant has significantly improved our project timelines. The plant’s efficiency and consistent output have resulted in higher quality concrete and reduced waste.

Mukasa Sam Mutebi

Purchase Manager

The control system on your concrete batching plant is truly user-friendly. It’s made managing operations much simpler, and the accuracy it provides in batching has noticeably improved the quality of our concrete.

Jude Imhanriaegbe

Project manager

The robustness and reliability of your concrete batching plant have exceeded our expectations. Despite the rigorous use, it’s maintained excellent performance, reducing downtime in our projects.

Samuel Hassani

Project manager

CASES

Latest Global Cases

September 06, 2023

35 Free Foundation Concrete Plant in Sri Lanka

September 06, 2023

YHZS35 Concrete Plant Arrived Indonesia

January 18, 2023

90 Dry Mix Mortar Plant Working in Indonesia

November 28, 2023

Belt Conveyor Concrete Plant Arrived Sri Lanka

May 27, 2023

Working Site of Concrete Batching Plant in Uzbekistan

October 25, 2023

HZS50 Concrete Plant Transported to Malaysia

September 20, 2023

HZS50 Concrete Plant Used in Thailand

January 15, 2023

HZS90 Concrete Plant Working in Tanzania

March 09, 2023

YHZS35 Mobile Concrete Plant in Botswana

SHIPMENT

Our Shipment Process

Process

At every step of our shipment process, our dedicated team takes great care to ensure that your order is handled with the utmost professionalism and attention to detail. We understand the importance of your satisfaction, and we strive to exceed your expectations with every shipment.

Order

24 online for your order

Production

Pick from stock or produce

Package

Well packed and labeled

Shipment

7 days fast delivery

EQUIPMENT